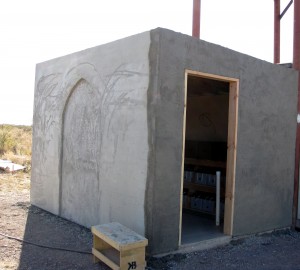

A passed inspection to proceed with stucco.

And we’re getting close. The paper and stucco netting are all on now. On Monday, we did something else I’ve been waiting for a long time: fire and ice. This is the last layer of underlayment…this one goes on top of the parapet as a final layer to keep water out. Fire and ice is a very thick vinyl with sticky black stuff on the bottom. We were going to put it on earlier, but it has to go over the sharkskin and house wrap paper. (Layers are put on from the bottom up so that water cascades down, hopefully never entering the house.) Fire and ice is kind of expensive, so Brad suggested we wait until the very end to do it. As it turns out, he was very right because we had to tear off all the paper because of wind. If we’d put fire and ice on before, we’d have had to tear it off and redo it too. Good call, Brad.

Fire and ice (blue and white top stuff) on top of the parapet

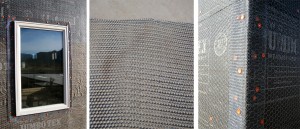

We also have most of the reinforcing lath that goes on all corners and around windows and doors. This stuff is a sheet of woven metal that goes on to strengthen places that might need it. It looked like it would be difficult to work with, but in fact, it was quite easy. It’s quite malleable, cutting and shaping easily. And it really looks great on the corners. It will make the rounded corners we’re doing much easier.

(Click to enlarge.)

We ran out of this stuff before we got the whole top of the house done, so it’s off to town to get more. Then, that should be it for lath.